SPInduwedge – Technical evaluation

Technical evaluation of the properties of SPInduwedge

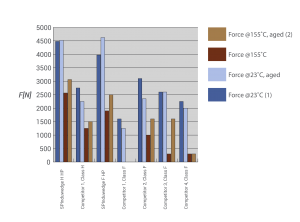

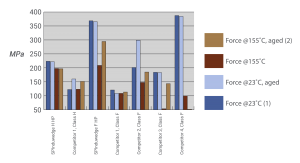

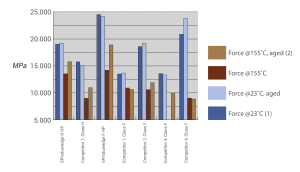

On the Vienna University of Technology an investigation was carried out to prove the stability of SPInduwedge and to compare the mechanical data with conventional magnetic slot wedges.

The results of this investigation are shown in the diagrams of this folder and in an descriptive 23-page booklet (Technical Report), which can be ordered from ASPIN.

The superiority of the mechanical properties of SPInduwedge can be seen when looking on the values of delamination load which corresponds to the force of inserting the wedge with a hammer (diagram 1), flexural strength (diagram 2) and module of elasticity (diagram 3). Moreover SPInduwedge react different to forces which normally damage the wedge, which can be seen in picture 1 to 3. These very pictures proves the superiority of SPInduwedge.