Magnetic Slot Wedges

SPInduwedge Slot Wedges are certified by UL

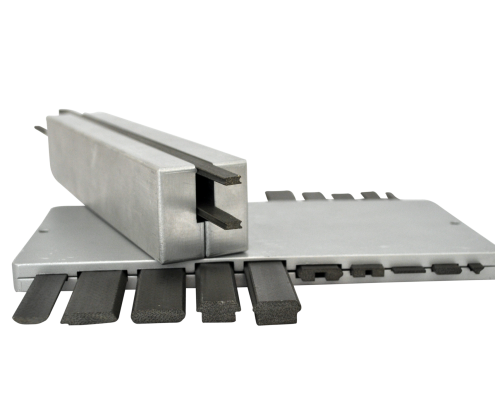

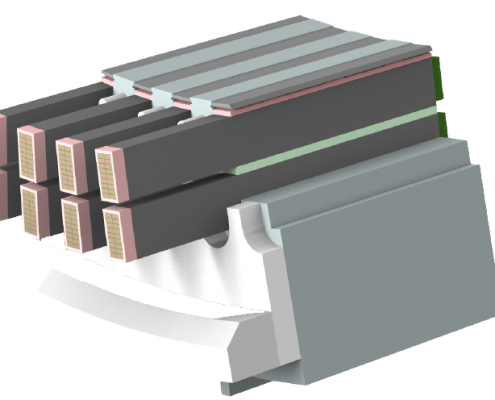

Slot Wedges

Magnetic and non Magnetic Slot Wedges

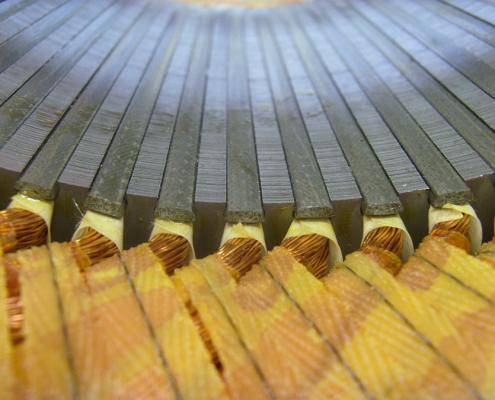

SPInduwedge Slot Wedges are made of either magnetic or nonmagnetic Material, being used as Slot Closures to hold the stator windings in the slots formed between the stator teeth.

Slot wedges made of magnetic material are a significant means to improve the efficiency of a motor or generator. Magnetic slot wedges reduce slot ripple in the air gap flux caused by the changing reluctance due to the slots, and also reduce the associated eddy current losses due to the interaction of the harmonics in the air gap flux with the conducting surface of the rotor.

The magnetizing current required in the stator windings to generate the desired air gap flux is less with magnetic slot wedges, since more of the air gap flux is available for useful power production.

Magnetic slot wedges reduce starting current, improve cos phi and load current, and lead to reduced iron loss (core loss).

Typical reduction of iron loss is in the range of some kW depending on the type of machine. This means a corresponding

value of some thousand Euros, when calculating the machine prize. So it is obvious that additional costs for high performance

slot wedges clearly pay off.

Conventional slot wedges are that weak that they often are not fulfilling the mechanical needs so that some companies are

not using magnetic wedges any more.

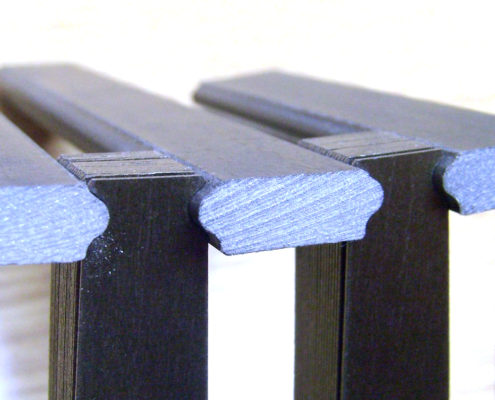

The mechanical properties of SPInduwedge – a new generation of magnetic slot wedges – are surpassing that of conventional

magnetic slot wedges (made out of laminated material) by far and it is to mention that they are in the range of non

magnetic (i.e. unfilled) glass fiber reinforced material, some non magnetic material they are even surpassing.

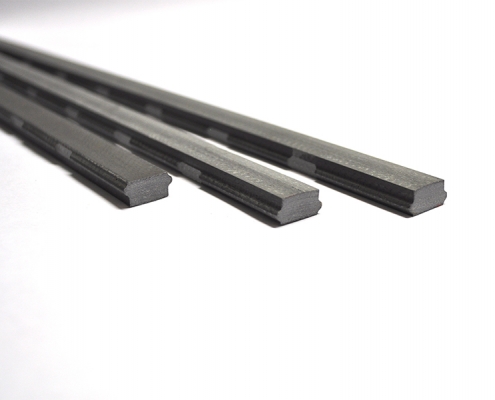

Further, our magnetic Slot wedges are not produced from Sheets which means a massive Improvement since cutting and grinding of Sheets with High Glass Content has a Major Impact on Health.

SPInduwedge (magnetic) Temperature Class F HP

Properties

SPInduwedge F [HP] – High Performance, is a rolled and pressed slot wedge made of special epoxy glassfibre ironpowder prepreg which has good magnetic conductivity and high electrical and thermal resistance combined with excellent mechanical strength.

Application

Magnetic slot wedges are used for example as induction motor, wind generator and traction motor – slot closure key.

Datasheets on enquiry (office@spindustries.at)

SPInduwedge (magnetic) Temperature Class H (HP)

Properties

SPInduwedge H [HP] – High Performance, is a rolled and pressed slot wedge made of special epoxy glassfibre ironpowder prepreg which has good magnetic conductivity and high electrical and thermal resistance combined with excellent mechanical strength.

Application

Magnetic slot wedges are used for example as induction motor, wind generator and traction motor – slot closure key.

Datasheets on enquiry (office@spindustries.at)

Slotwedge Information Folder & Test Results

- Information folder about the unique advantages and properties of SPInduwedge Magnetic slot wedges.

- Our Magnetic slot wedges have been extensively tested for their mechanical properties at the Technical University of Vienna.

to prove the stability of SPInduwedge and to compare the mechanical data with conventional magnetic slot wedges. The results of this investigation are shown in the diagrams of this folder and in an descriptive 23-page booklet (Technical Report), which can be downloaded here.

This extremely high flexibility is a result of SPI’s patented Production Process. If you try this with any Competitors Wedge, it will most likely break or delaminate.