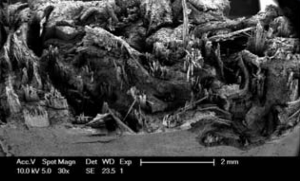

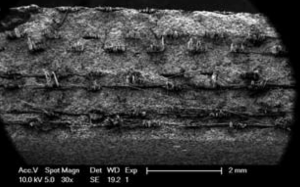

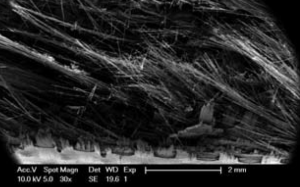

SPInduwedge – Scanning electron micrograph pictures

Scanning electron micrograph pictures from the surface of fractures show the difference in the construction. The production process of the SPInduwedge slot wedge is a break through and completely new. A rolled glass cloth is used, which is pressed with a resin iron powder mixture in a specific press. The rolled cloth is responsible that SPInduwedge material has virtually the same mechanical stability in all directions.